Brand: Yiying Packaging

Product origin:China

Material structure:

Mono or multi-layer laminated materials,such as:PET/VMPET/PE, MDOPE/PE, BOPE/PE and PET/AL/RCPP etc.(according to requirement)

Application: whole beans, ground coffee and instant coffee etc.

Supply capacity:200 tons/week

Delivery time:30 days lead time

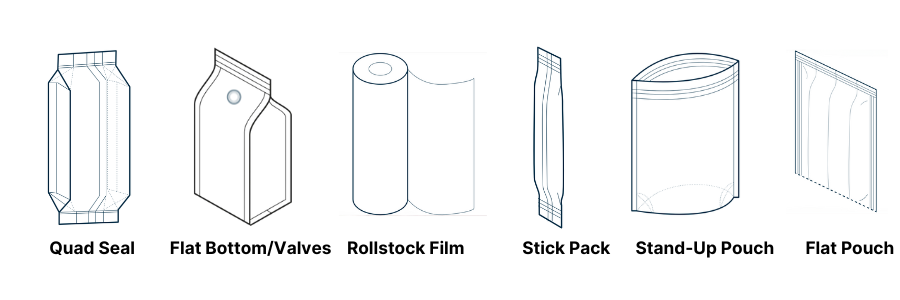

Quad Seal Pouches

The 4-side seal coffee bag is typically manufactured as a pre-formed pouch, ready to be filled and sealed by coffee manufacturers or packaging companies. The packaging bag can be equipped with various features, including a resealable zipper, degassing valve (for freshly roasted coffee), tear notches for easy opening, and a printable surface for branding and product information.

- High vapor barriers that block moisture, oxygen, and aroma from entering or exiting the package

- Guaranteed to be of the highest quality and durability

- Puncture and tear-resistant

- SUSTAINABILITY: Our flat bottom pouches are available in PCR materials, reducing waste and environmental impact.

- Versatility: Ideal for coffee, dry goods, snacks, and more.

- Available in a wide range of colors and sizes from 8 oz. to 50 lb.

- Utilize multi-ply barriers with adhesive lamination to provide superior product protection

-Can be customized to include value-added features such as degassing valves and easy-open capability

Our custom-printed Coffee Packaging bags allow you to choose the sizes and features that best suit your needs. Packaging can be customized with branded graphics and additional features including innovative one-way degassing valves and zipper closures to ensure optimal flavor and freshness. Among the most common coffee containers on the market, we find: Stand up pouches (Doypacks), Flat-bottom, Side-Gusset bags, capsules and Flat pouches (pillow bags).

Regardless of the format of the product, the packaging will have to preserve the aroma and taste, so the barrier layers will be essential for the final quality of the product.

-Oxygen, light, and moisture barriers that meet stringent requirements (including clear high-barrier laminations)

-Easy-open format enhances convenience

-Keep your PRODUCTS fresh and extend shelf life with high-barrier lamination protection against oxygen and moisture

-5- 8 ounce to 5 pound bags

-integrated valve solution can be incorporated on any of Yiying’s typical 3-4ply retail bags, and adapted to your specifications

At Yiying we have the BRC certificate that guarantees compliance with GMP regulations (in addition to ISO 9001) in the manufacture of complex materials intended for medicine packaging.Many leading pharmaceutical and medical device manufacturers choose Yiying to supply foil & non-foil flexible packaging laminations

Experience: 22 years in the plastic flexible packaging industry

Innovation: Leader in integrated solutions and technological innovation

Environmental Focus: Emphasis on green environmental protection concepts and environmentally friendly products

Certifications: Manufacturing processes comply with ISO9001, ISO14001, ISO13485, ISO45001, and BRCGS standards

Sales: 200 million annual sales

Facility Size: 40,000 m2 factory

Customer Base: Serves a wide range of customers, from small manufacturers to Fortune 500 companies

Notable Clients: KINGFA, Nestle, and Arkema

our packaging engineers can reverse engineer existing flexible packaging in the marketplace to help you determine what flexible packaging materials are being used for existing products.

This testing determines how your product interacts with various flexible packaging structures, and will help with identifying adverse effects that a product has on flexible packaging materials, such as chemical degradation or delamination. This testing is an invaluable tool when selecting flexible packaging materials that will perform over time.

We can suggest pouch dimensions based on the product type, volume, and develop pouch mockups or proto types in various configurations.

Our packaging engineers provide comprehensive package design services,helping you bring your package from conception to engineering to production. Collaborating and brainstorming with you to ensure your packaging meets the goals of all stakeholders, our packaging engineers can create innovative package or stand up pouch prototypes printed with your own graphics, incorporating unique shapes, fitments, and other value-added features that provide convenience and shelf impact. Our knowledgeable packaging engineers have been invited to speak as pouch experts at several industry conferences, and they have helped leading brands convert to stand up pouches.

Our packaging engineers will subject your packaging to various types of testing, which may include:

- Product/package compatibility testing

- Compression testing

- Inter layer adhesion testing seal testing

- Puncture resistance testing

- Tensile testing burst testing

- Drop testing