Mono-material packaging: a smart and really sustainable solution

It is well known that packaging for food use constitute a large percentage of the total waste produced every day. Even though on several fronts the tendency is to reduce the quantity of packaging, it’s undeniable that in the large distribution many products still require a plastic packaging, which, to the present day, is the only one capable of guaranteeing high performances for food protection and preservation.

On the other hand, despite users’ awareness considerably increased for what concerns separate collection and recycling, product packages can often be deceptive or, even more frequently, are realized with different types of materials. This ambiguity leads consumers to renounce a meticulous separation and to throw everything in a single container.

This is why, for promoting recycling and make it an easy and really efficient task, it is necessary to adopt a packaging not only attractive and practical, but also sustainable! How? By means of mono-material packages.

What’s mono-materials ?

A mono-material is a product which is only composed of a single type of material. Products could be made out of paper, plastic, glass, fabric, metal or other materials.

Because they only consist of a single material, mono-materials are typically easier to recycle than products made from different materials. An added benefit is that they generally use less energy to recycle because a ‘pre-stage’ of splitting or dividing the various materials apart doesn’t have to be taken into account.

The overall recycling process is faster, more efficient, less energy-intensive and more cost-effective.

Mono-materials are particularly crucial for the packaging industry because anything that can’t be recycled is going to landfill. Because packaging is so plentiful, any reduction in landfill or increase in packaging that can be recycled is hugely beneficial to the environment.

Packaging that uses lots of different materials has been the norm, but increasingly, brands are looking to switch to mono-materials. They hope that this will make their packaging more eco-friendly, sustainable and easily recyclable, supporting a circular economy.

How Yiying Packaging can help?

we use mono polymer technology to make packaging that is 100% recyclable. We have worked with businesses to construct mono material films from single polymer resin to produce packaging that is sustainable and attractive.

We understand that making the switch to sustainable packaging isn’t always easy. But we can work with you to find the right packaging solution for your product.

Introduction of Yiying 100% Recyclable Plastic Bags:

Flexible packages can be recycled only after the layers composited had been separated, because most of flexible packages are made from different types of film laminated together. Yiying recyclable bags use pure PP or PE structure, so that the recycling can be carried out directly without the rigmarole material separating process.

Yiying 100% recyclable plastic bag is the real recyclable packaging. As we use single material pure PP or PE instead of traditional composite material, which improve the use value of materials, reduce environmental pollution and meet the needs of economic development.

How to Achieve Barrier Properties for the Single Material Recyclable Plastic Bag?

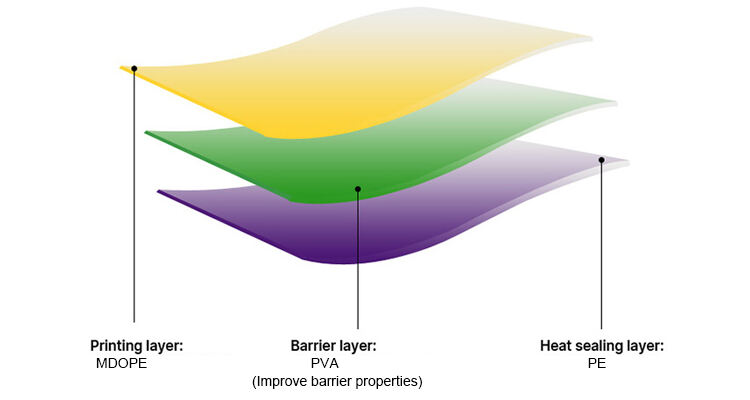

Yiying Single Material 100% Recyclable Plastic Bag gains good barrier performance by PVA coating and MDOPE film, its barrier properties to prevent or minimized the passage of external elements such as moisture, oxygen, light and odors into the packaged food is very closed to the traditional multi materials lamination plastic bag. In this way, it can maintain the safety and shelf life of the packaged food products.

Application:

Food Packaging Industry: packaging for snack, dry foods, fresh food,coffee pet food, pet treat and accessories ect.

Personal Care & House Hold Industry: packaging for makeup tools, detergent and cleaning products ect.

Pharmaceutical Industry: packaging for medicines, medical devices ect.