Plastics, short for plasticity macromolecular materials, are organic polymeric materials consisting of giant organic molecules. Because of its malleability and plasticity during manufacture, plastic materials can be formed into kinds of shapes, such as films, fibers,plates, tubes, bottles, boxes, and much more, by one of a variety of processes, such as extrusion, molding, casting or spinning. And therefore, plastic materials are used in a huge and growing range of applications from packaging to buildings, from cars to medical devices,toys,clothes etc..

There are two broad categories of plastic materials: thermoplastics and thermosetting plastics. Thermoplastics can be heated up to form PRODUCTS and then if these end products are re-heated, the plastics will soften and melt again. In contrast, thermosetting plastics can be melted and formed, but once they take shape after being solidified,they stay solid and, unlike thermoplastics, cannot be remelted.

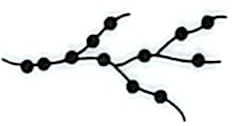

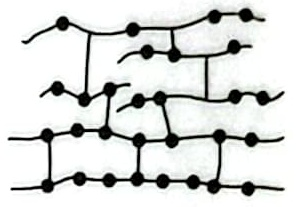

Polymers are made of a series of repeating units known as monomers. The structure (as is shown in figure 3-1) and degree of polymerization of a given polymer determines its characteristics. Linear polymer (a single linear chain of monomers) and branched polymers (linear with side chains) are thermoplastics. Cross-linked polymers (two or more chains joined by side chains) are thermosetting plastics.

(a)linear polymer straight chain

(b) branched polymer

(c)cross-linked polymer

crimp chain

Figure 3-1 Polymer structures

*Familiar Thermoplastics Used in Packaging*

Polyethylene, the most widely used plastic packaging material,is an ivory-white, semitransparent or opaque, ceraceous solid plastic. Generally,PE is almost odorless, nontoxic, heat seal-able, and it has good moisture barrier property, chemical stability,good resistance to acids, alkalis, solvents, and excellent electrical insulation as well. As packaging material, PE also has some disadvantages,such as relatively high gas permeability, poor resistance to heat, lower strength,worse printability, and so on. PE is widely used in packaging fruits, making bags and mostly used in cosmetic packaging.

Polypropylene is similar to PE in appearance, but it is more transparent. The advantages of PP include excellent moisture barrier and water-proof properties, heat sealability,better resistance to the permeability for peculiar smell than PE,perfect fatigue resistance and bending strength etc. PP also has some shortages,for instance,poor resistance to freeze and aging, low gas barrier property, etc. PP has a wide application in making packaging containers which are used for foods, chemical products, and cosmetics, such as cases,bottles, woven bags, films, straps, and foam cushion materials etc.

Polystyrene is a kind of colorless, transparent, odorless and nontoxic material. PS film has excellent transparence and gloss,good dyeing property and printability, low water absorption,good dimensional stability and rigidity. The disadvantages of PS include low strength of resistance to impacting, lower surface hardness,poor moisture barrier property, low resistance to heat and oils, and so on. PS is widely used in making small containers used for foods,pharmaceuticals and commodities etc.

Polyvinyl chloride possesses a series of advantages, such as excellent mechanical strength,wear-resisting property,compression strength, moisture and gas barrier properties, printability,and resistance to strong acids and alkalis etc. But attentions should be paid to the migration of some harmful compounds from plasticized PVC into food. PVC is mainly used to manufacture rigid packaging containers, transparent sheets, flexible packaging films, and foam cushion materials.

The excellent oxygen and moisture barrier properties of PVDC make it a ideal material for packaging converters in recent years.But the high cost of PVDC tends to mean that it is mainly used in the form of copolymers.

PET is a very strong clear glossy film, and possesses a great number of advantages, such as good moisture and gas barrier properties,tensile strength, adaptability to environmental protection,little shrinkage with variations in temperature or humidity,good printability, and so on. The main disadvantages include low resistance to strong acids and alkalis, bad heat sealability,high cost etc. PET is mainly used in manufacturing bottles used for carbonated drinks and mineral water, or films used for boil-in-bag.

Plastics possess a number of extremely desirable characteristics compared with other materials. For instance:

a. Lightweight: the density of most plastic materials is relatively low.

b. Good transparence: some of plastic materials are transparent,which makes optical devices possible.

c. Excellent corrosion resistance: plastics are resistant to acids, alkalis and solvents.

d. Excellent thermal and electrical insulation properties: however,some can even be made as conductors of electricity when required.

e. Good moisture barrier properties.

f. Proper mechanical strength.

g. Ease of manufacture.

Plastic containers in common use include bags, pouches, cases,barrels,bottles,flexible tubes etc.

Plastic bags are flexible packaging containers made of single layer of plastic film or more layers of combined films. Plastic bags are widely used in packaging because of their excellent characteristics, such as lightweight,transparence,

resistance to folding, puncture,acids,etc.

Plastic cases (Figure 3-2) have two main categories: plastic turnover box and calp box, which have very extensive applications in packaging. Plastic turnover boxes are mainly made from HDPE and PP with high impact strength by injection molding and widely used for transporting goods, drinks, beer,vegetables,and fruits,etc. Calp box is a special type of folding box that is patterned after the sample of corrugated box with calp corrugated board.

Figure 3-2 Plastic case

Plastic barrels (Figure 3-3) are mainly formed by extrusion blow molding and rotational forming. Plastic barrels possess a series of advantages,such as light weight,chip-proof, corrosion resistance,etc.,which makes it possible to contain chemical products, oils, pickled food instead of some of the metal drum, wood cask, or glass cans,etc.

Figure 3-3 Plastic barrel

Plastic bottles (Figure 3-4), sales package containers, are mainly manufactured by one of two processes: extrusion blow molding or stretch blow molding. The raw materials of plastic bottles include PE, PP,PVC, PET, PS,PC,and NY,etc. The advantages of plastic bottles include lightweight, chip-proof,high strength,good chemical stability, ease of printing and decorating, and so on. Therefore,plastic bottles have extensive applications in the packaging of liquid, pulpy and solid products, such as food,drink,chemicals,cosmetics,medical supplies,oil, and fuel etc.

Figure 3-4 Plastic bottle

The body of plastic tube (Figure 3-5) is commonly manufactured by extrusion, while the shoulder and neck of the tube are formed by injection molding. Then the body is welded together with the shoulder and neck to form the plastic tube. Materials used to make plastic tube include LDPE, PP, PVC, NY, etc. Plastic tube has a series of advantages, such as lightweight, good flexibility and elasticity,and chemical stability etc. Therefore, it is mainly used to pack cosmetics,medication,foodstuffs,watercolors and chemical products etc.